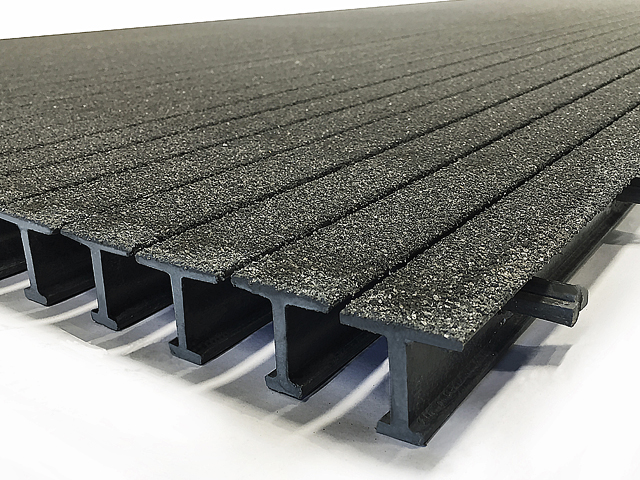

PULTRUDED GRATING

TerraGrate® Pultruded Grating is a series of high strength pultruded bars that are the best solution for replacing aluminium and steel gratings in corrosive environments. Pultruded gratings are designed for use in a wide range of industrial applications where longer support spans are required.

PRODUCTION PROCESS OF TERRAGRATE®

TerraGrate® FRP Pultruded Grating is manufactured by assembling two structural fibreglass T bearing bars into a grid pattern. The T bars structural shapes are made by pultrusion – a continuous moulding process utilising fibre or glass reinforcement in a polyester or vinyl ester resin. Selected reinforcement materials are thoroughly infused with the high-quality resin, the fibrous laminate is formed into a geometric T shape and pulled through the heated steel dye. This solidifies into the exact shape of the dye cavity as it is being continuously pulled by the pultrusion machine.

KEY FEATURES & BENEFITS

- 65 percent glass and 35 percent resin, giving it a very high strength to weight ratio

- Weighs 50-70 percent less than steel gratings

- High load capacity (HI), up to H20 vehicle load

- Manufactured with resins containing UV inhibitors

- Flame spread rating of 25, accordance with ASTM E-84

- Self-extinguishing requirements of ASTM D-635

- Durable gritted surface, superior slip resistance

- High density but lightweight

- Electric and heat insulated

- Low temperate resistance

- 316 Stainless steel attachment system

- Low Installation/maintenance cost

Website

Send Enquiry To Terra Firma | TerraGrate FRP