THE NEW EUREKA MODULAR RESTROOM SERIES

22 Apr 2021

As Australia’s leading provider of prefabricated restrooms, Landmark Products’ Eureka Modular Restroom Series incorporates more than 30 years’ experience in designing and manufacturing restrooms – specifically for Australia’s diverse environment.

Featuring a contemporary design, the modular Eureka Series from Landmark Products blends into all open space environments and is available in various sizes in order to meet every community need. This includes large cubicles for people with disabilities. Made with quality materials and finishes, the restrooms are 100 percent Australian-made and designed to withstand public use in all Australian environments. Other features include:

- Warranty Available

- 10-year supply only

- 20-year supply and installation

- National Installation Service

- Full Site-Specific Engineering Certification (All Structures)

- Wind Classification of C2 (Cyclonic Regions)

The series modular design provides many benefits, including:

Time

- On average, a modular building is constructed percent faster than one using traditional methods

- Delivered using direct haul from factory, non-stop transport to site - reducing risk of damage

Relocatable

- Ability to lift out modular buildings and re-use in other locations

Testing and Commissioning

- Performed by highly skilled personnel, any potential faults are identified prior to site delivery

Budget

- Modular buildings can be more affordable than site-built buildings

- Shorter build time tends to mean significant cost savings

- There are decreased obstructions in the process of waiting for materials

Weather

- As the major parts of construction are carried out in a factory, the risk of being rained off is reduced with modular builds

- Vandalism presents to be far less of a problem as a result

Health, Safety and Quality

- Factory conditions allow for far greater control and improvement of health, safety and quality compared with the traditional building site

Environmentally Friendly

- Modular builds demonstrate a higher energy-efficiency and creates less waste

- Reduction in the carbon footprint of the build as fewer people are travelling to and from the site

Reduced Community Disruption

- Modular builds create less noise, traffic, mess and disruption for the local community

Does Modular Construction use inferior materials?

No, all the same materials, fixtures and fittings that are used in traditional construction are also used in modular construction. Landmark Products use a range of leading brands in the construction of its buildings and are proud of the quality that comes with its products.

How does Modular Construction work?

Modular building uses Landmark Products’ state of the art, purpose-built factories to complete much of the construction task in a production line environment. Skilled tradespeople work as a team to deliver a high-quality, reliable and consistent building, that is then tested and transported to site. Assembly on-site is a relatively quick and easy process, as the building is completed and any services (e.g. electricity, water and the like) are connected and tested.

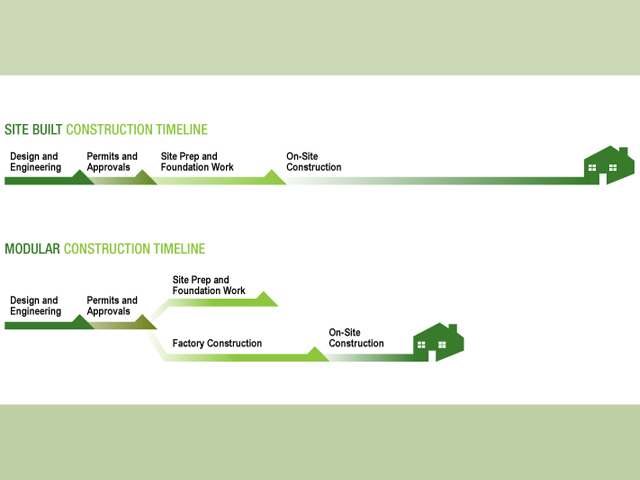

How is Modular Construction faster than traditional construction?

With much of the building work taking place off-site in purpose-built factories, delays due to adverse weather are all but eliminated. Also, time spent on-site is significantly reduced. Depending on the complexity of the site and design, the on-site time could be as little as 2-4 days!

Find out how Landmark Products can help you with your next project via the links below.